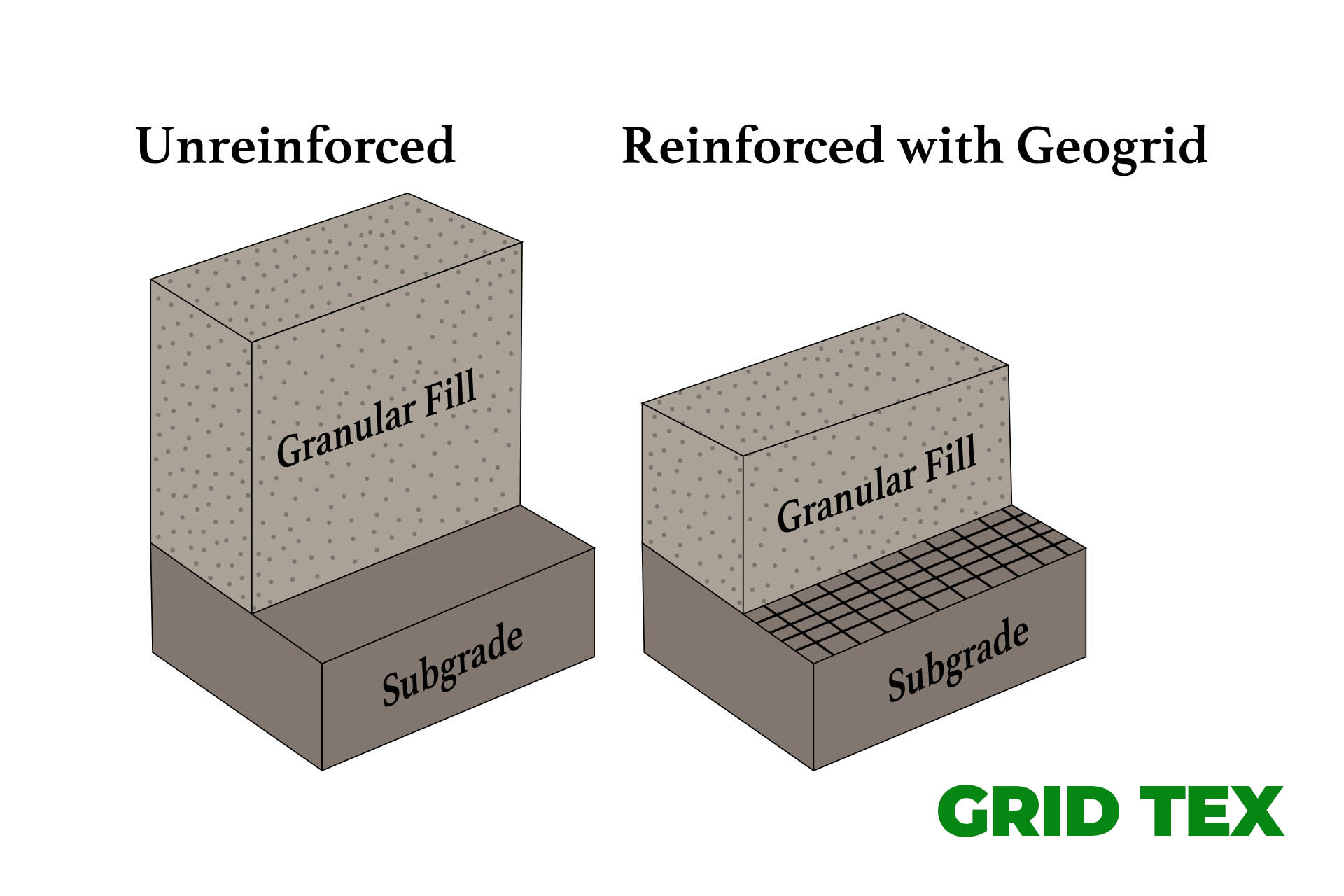

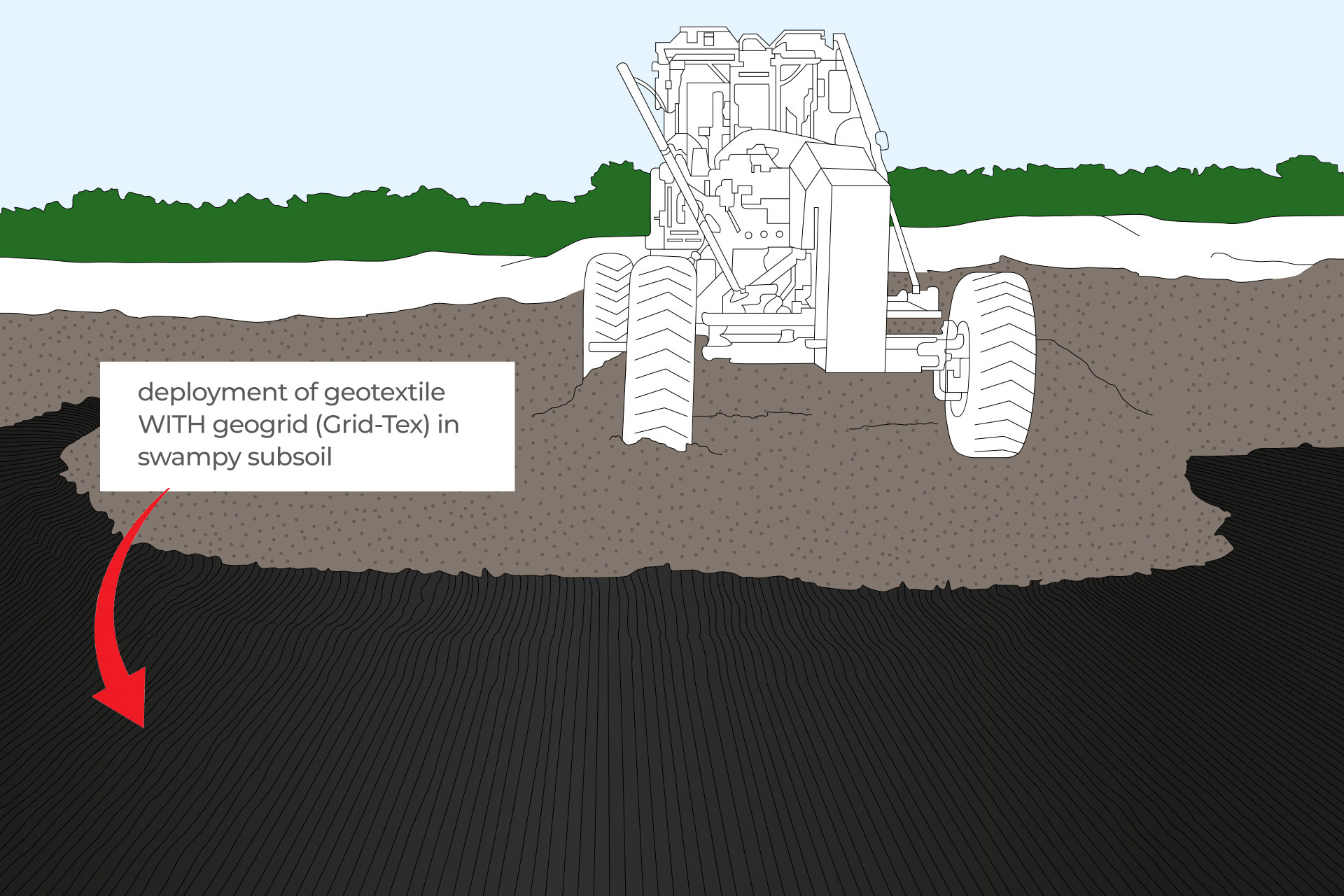

The high-tech union of two proven geosynthetics is known as composite-geogrid, offering confining properties with the geogrid and ease of filtration and separation with the geotextile providing a new tool to combat weak soils.

When faced with undesirable subsoils this "composite geogrid" provides a cost effective method of "bypassing" problem soils.

Main Benefits:

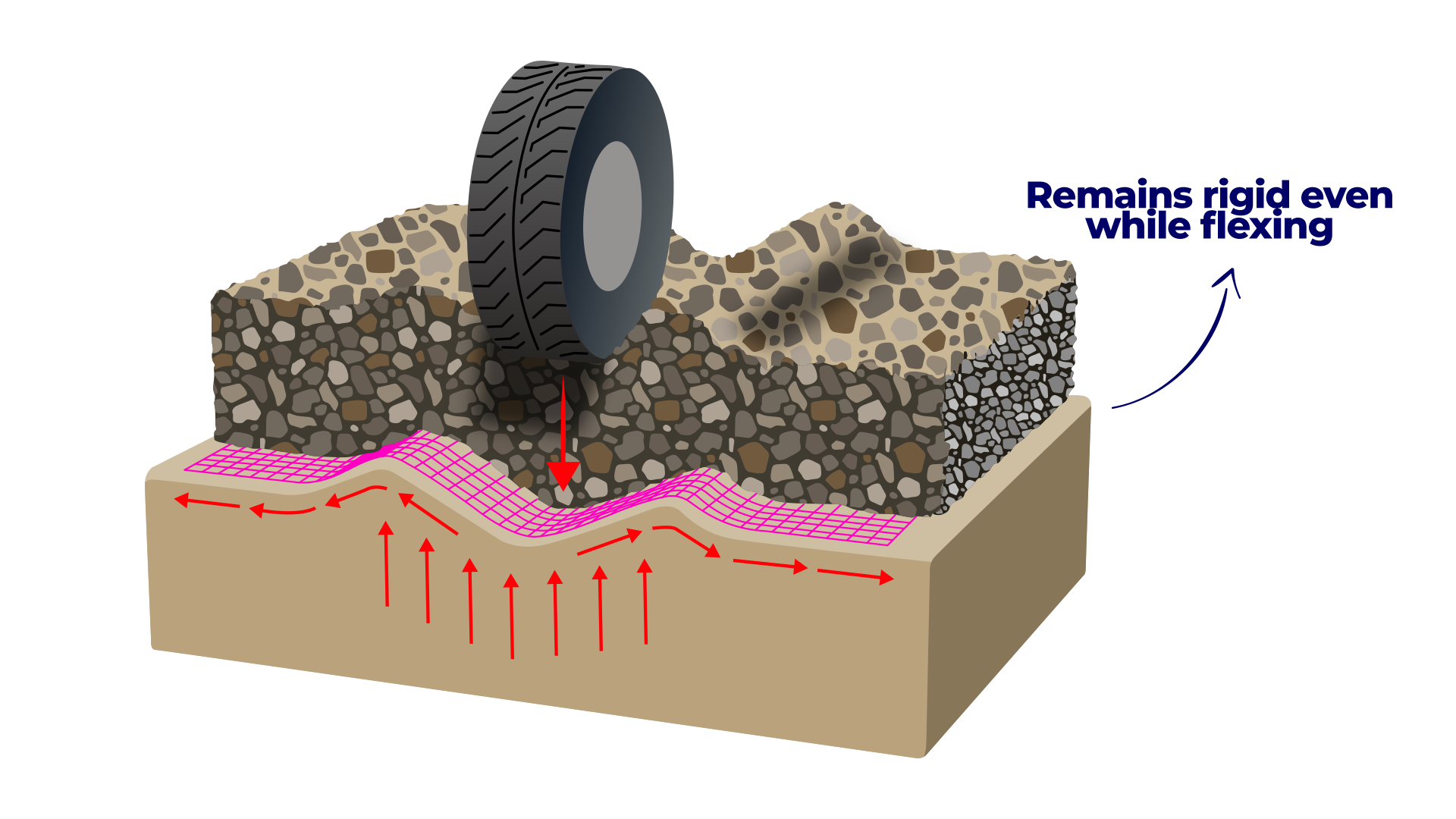

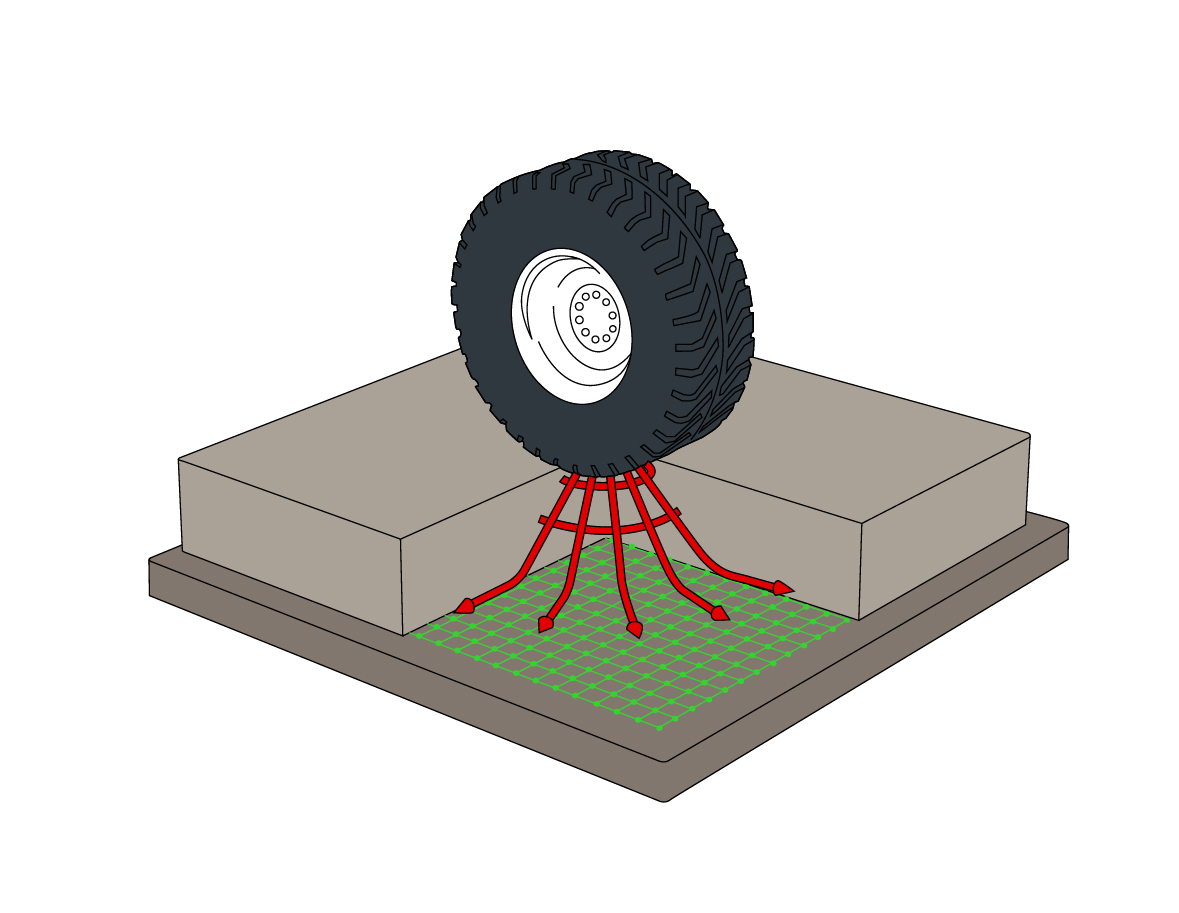

• Reduction of aggregate thickness required typically by 50 to 60 percent

• Avoid the need for undercut

• Faster and more effective construction

• Paved Applications: Extended design life, life cycle cost benefits (reduction of repairs)

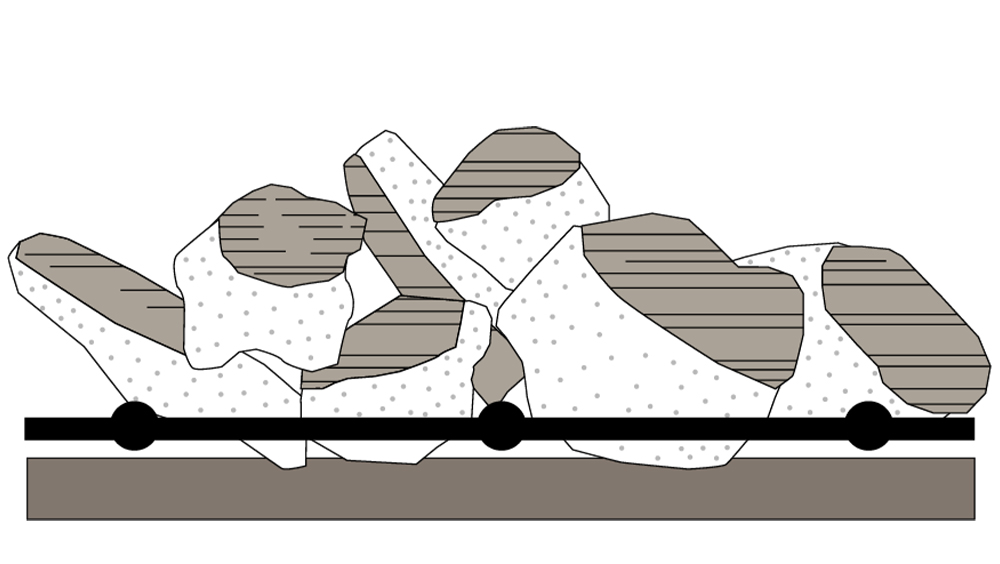

Exclusive nodule lamination

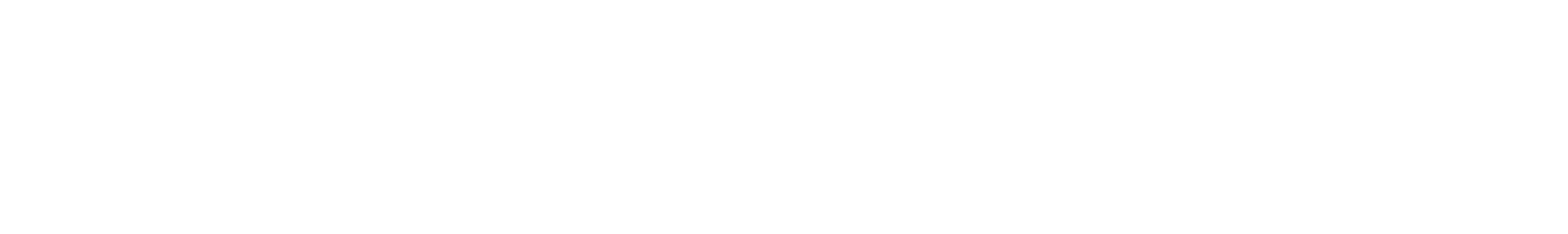

Grid-Tex is created when a non-woven geotextile is laminated to a geogrid, it is very important to note that the geotextile is only laminated to the nodule of the geogrid; this eliminates what is known as the "trampoline effect.”

The separation of the nodule and the geotextile allows the aggregate to pass through and interlock superiorly to the entire geogrid system.

When complete lamination of the geogrid (lamination of the geotextile to the entire lower surface of the geogrid) is carried out, the interlacing ability through the aggregates on top is restricted. This "trampolone effect" hinders the functionality of the geogrid.

Additionally, Grid-Tex can laminate nonwoven geotextile to the geogrid without melting or compromising any part of the product; many other items on the market feature smaller, thinner openings that cannot withstand the heat bonding process without compromising product integrity.

Grid-Tex's proven technology allows for proper bonding of geotextile and geogrid, without damaging the product itself.

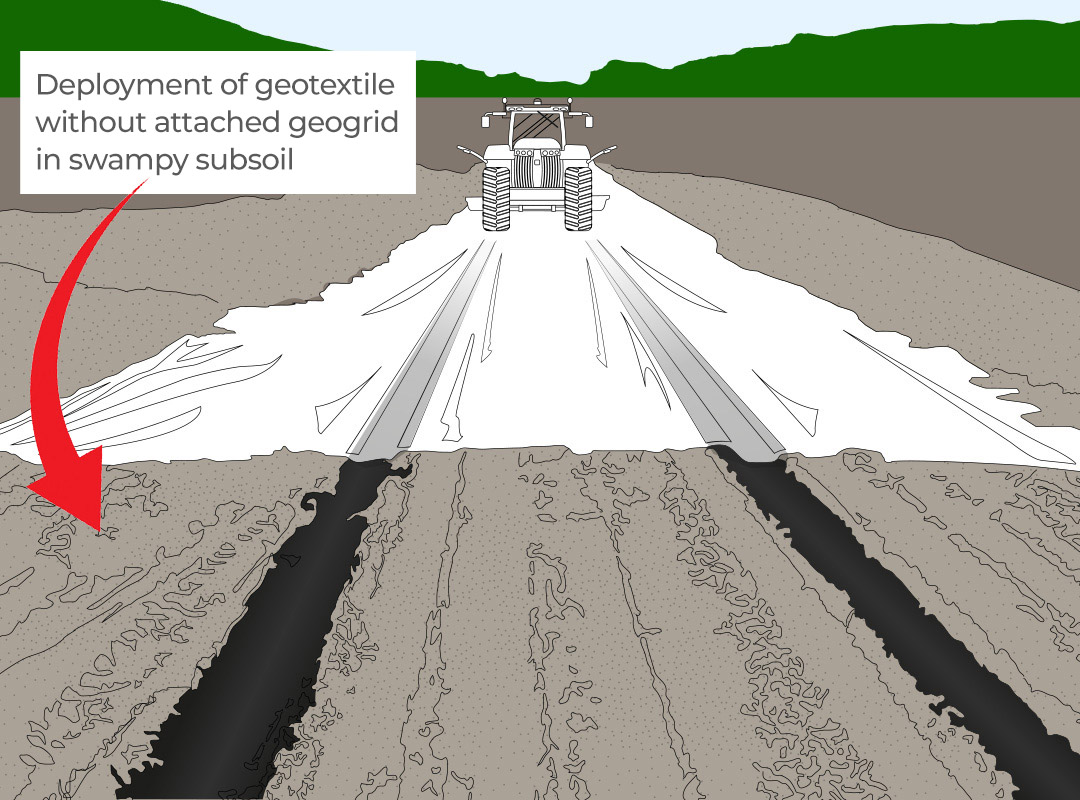

The standard application...

at this time is to unroll the non-woven geotextile and then put a geogrid back on top, The problem with that is that if we unrolled the geotextile on an unstable environment we would not have any support or tension, the union between the georgic and the geotextile facilitates in this specific case; the deployment of the geogrid by itself in an unstable humid environment. Preventing migration and pumping of material that would avoid proper entanglement of the aggregate fill material with the geosynthetic itself. So by combining both products we are achieving immediate separation and filtration and also distributing the load by pushing the fill rock on top of the product in order to tighten the base section.

We are able to help do specific tests in the subsoil determining the correct product for the application, specially regarding the opening and thickness of the geogrid and the thickness of the geotextile.

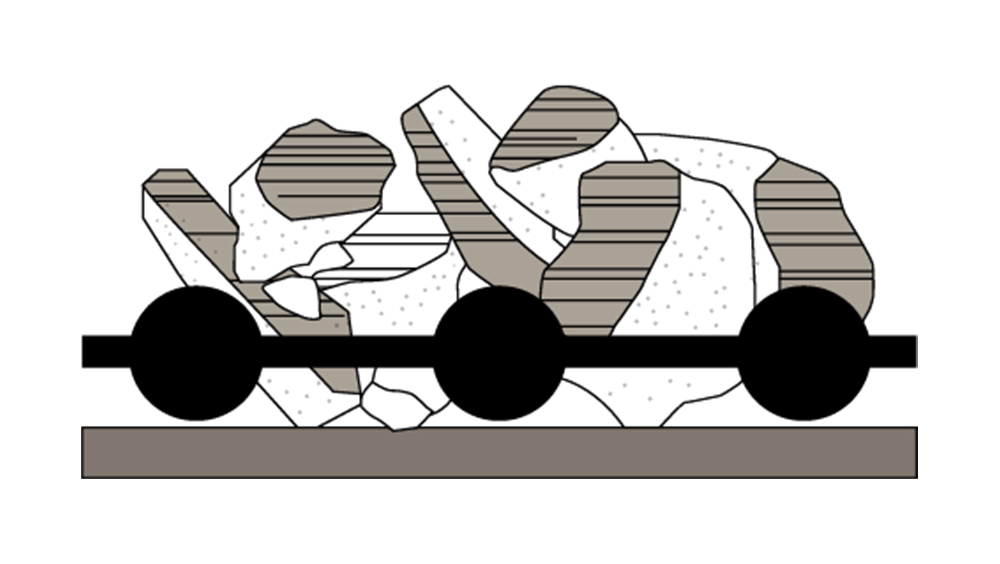

When we talk about applications that do not need a filtration layer, a biaxial geogrid is used with the objective of tightening the section to be built or paved, providing a simple and cost-effective solution for soil reinforcement; improving roads, highways, and other high-traffic areas.

Even when conditions are not perfect, including: weak subgrade, contaminated soils, heavy loads, high granular fill costs, and shallow utilities, an engineered solution is possible.

Examples: Roads, Rail Ballast, Site Access Roads, Haul Roads, Parking Lots, Industrial Shipping Yards, Foundation Pads.ceso al sitio, Caminos de acarreo, Estacionamientos, Astilleros industriales de envío y Zapatas de cimientos