Success story

RESTORATION OF LAKE NANKIN, LIVONIA MICHIGAN USA 2023

A multi-million dollar restoration project is under way on Lake Nankin. Locals have noticed the large white tarps and heavy equipment along Hines Drive Avenue lately.

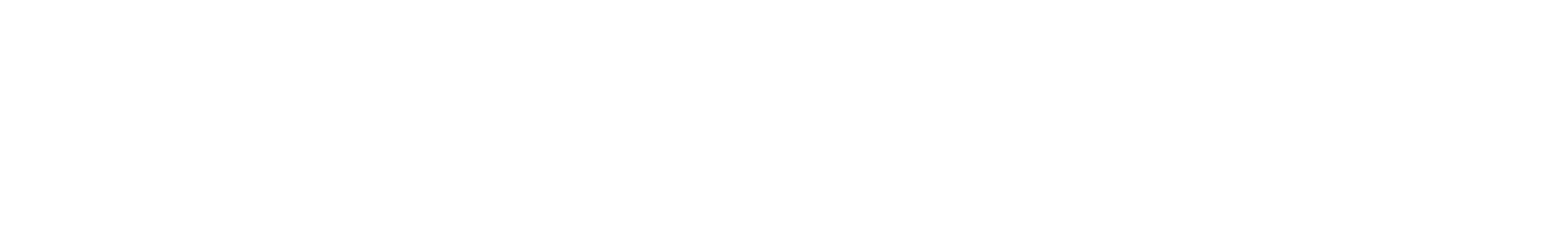

The project aims to restore fish habitat as well as increase the amount of water the lake can hold during severe storms. Along Over the years, Nankin Lake has slowly been filled with sediment and other debris. Because of this accumulation, it has become shallow in many areas and has islands visible, which reduces the total surface area of water and fish habitat.

These continuing problems have led the

Environmental Protection Agency

to declare the waterway as an "area of concern". Thanks to the dedication and hard work of groups such asFriends of the Rouge

,Alliance of Rouge Communities

and many more, something is being done. to clean the lake and the surrounding streams.Wayne County received an EPA grant for the restoration and work will continue over the next two years. Maintenance will be continuous.

OBJECTIVES OF THE LAKE RESTORATION PROJECT.

The Lake Nankin restoration project will ensure ecosystem functions that provides the lake; including valuable spawning, breeding and fish and other species from all stages of life.

As part of restoration efforts, sediment will be removed and will reform the reservoir basin to create a more open water habitat and provide a deep-water habitat for fish during the winter. A sedimentation bay will also be built as part of the project.

This will work to capture sediment and debris from the river before it enters the lake. The sediment bay will also provide Wayne County with a place to monitor the lake and provide maintenance when conditions require.

The deep water provides the necessary conditions to spend the winter in the lake, ensuring the survival of the inhabitants of the lake. The construction of the deep-water habitat will involve the removal of sediments and the creation of habitat.

TECHNOLOGY

Sludge dehydration through our solution

TubeMax®

especially designed for efficient environmental sludge drying applications, a solution of high volume and low cost dehydration how our containersTubeMax®

offers an effective drainage technology made from a special fabric designed to provide confinement of fine solids within the container, to the time that allows water to penetrate through the designed fabric.As water drains, solids continue to densify and consolidate over time. Once solids are fully consolidated or have met the minimum requirements for transport, there are several options available for the removal of dehydrated material.

The containers for dehydration

TubeMax®

are designed to optimize the retention of solids and the rate and quality of discharge of effluents, which makes them a highly efficient and environmentally friendly solution for various sludge dewatering applications.

dehydration of

TubeMax®

is a three-step process:Step 1: Filling

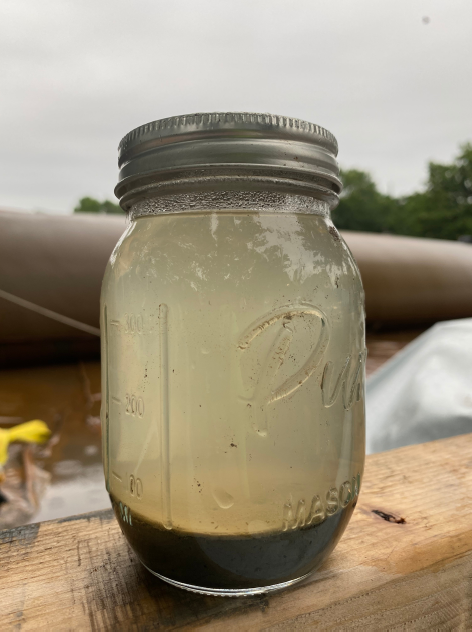

Sludge (sludge material) is pumped into the container

TubeMax®

. Polymers are added environmentally safe to sludge, causing solids to bind and water to separate.

Step 2: Dehydration

Clear effluent water simply drains from theTubeMax®

container through the small pores in specially designed fabric.This results in effective dehydration and an efficient reduction in the volume of materials contained.

Volume reduction allows repeated filling of the container

Step 3: Consolidation

After the final fill and drain cycle, solids remain in the bag and continue to densify due to drying as the residual water vapor escapes through the fabric.Volume reduction can reach 90 percent. When full, the container and content of

TubeMax

can be deposited in a landfill, remain on site or solids can be removed and applied to the ground when appropriate.